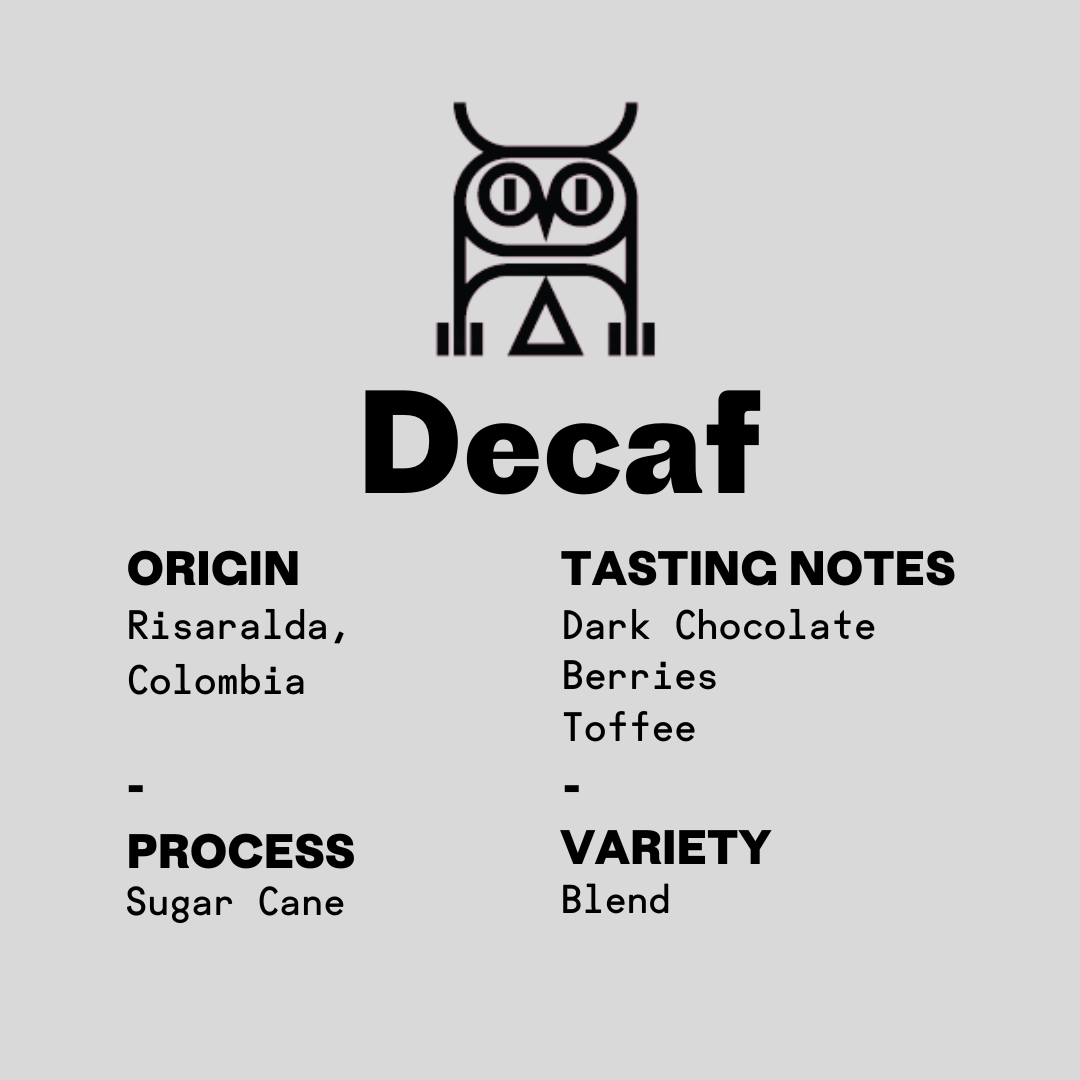

Decaf Sugar Cane Process

$17.00 - $102.00

Who says decaf has to be dull? Our Sugar Cane Process decaf retains all the rich flavors you love without the caffeine kick. Enjoy a smooth, sweet cup with notes of caramel and a whisper of fruitiness—perfect for late-night indulgence or when you're simply dialing down the jitters. 5lb bags enjoy free shipping and an extra 10% savings automatically!

Check our playlist pairing below or follow us on Spotify to enjoy tracks curated for all your favorite coffees